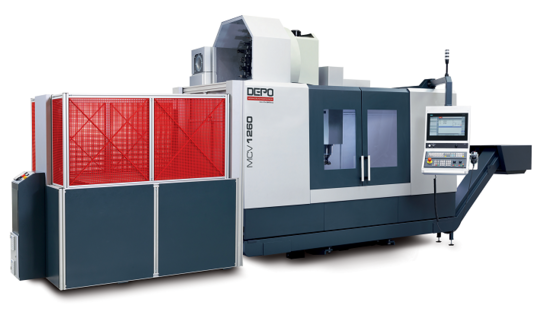

DEPO - MCV Vertical Series CNC Machining Centres

Milling without Compromise

The vertical machining centres of the MCV series convince by highest performance and accuracy as well as special reliability and durability. The mechanical stability of the machines is characterized by the robust column construction with reinforced cross-ribbing. Thermal stability is guaranteed by the design of the headstock and its cooling circuit. The robust machines of the MCV series are thus equipped with everything required for rough machining of heavy workpieces as well as for finishing operations. The ball screws and linear guides meet the highest precision requirements and allow the machine to be highly dynamic with rapid traverse rates of 40 m/min. Manual scraping of the contact surfaces on the machine bed and column meet the highest quality requirements. Optionally, the machines can be expanded for 4- or 5-axis machining and equipped with an automatic pallet changer.

Call BSA Tools Ltd - Customer Service Department for full Details !!

Milling without Compromise

THE MCV EQUIPMENT INCLUDES

The MCV series is already equipped with everything you need for a direct start into 3-axis machining in the standard version.

Of course, you can expand it with a wide range of options.

Standard equipment on the MCV

SIEMENS 840 D, HEIDENHAIN TNC 640 or FANUC 31i

Direct measuring system in all axes

CYTEC-Spindle with 15.000 rpm 40/48 kW, 280/340 Nm (S1/S6)

Internal cooling supply

Double sliding doors for best accessibility to the workpiece

Tool magazine with automatic tool changer and 24 pockets

Signal lamp

Chip conveyor

Options Available

Additional swivel rotary table with 4. and 5. axis

Workpiece measuring probe

Additional tool magazine capacity

Tool measuring system

Workspace flushing

Oil and emulsion mist extraction

Vibration Analysis

Remote maintenance

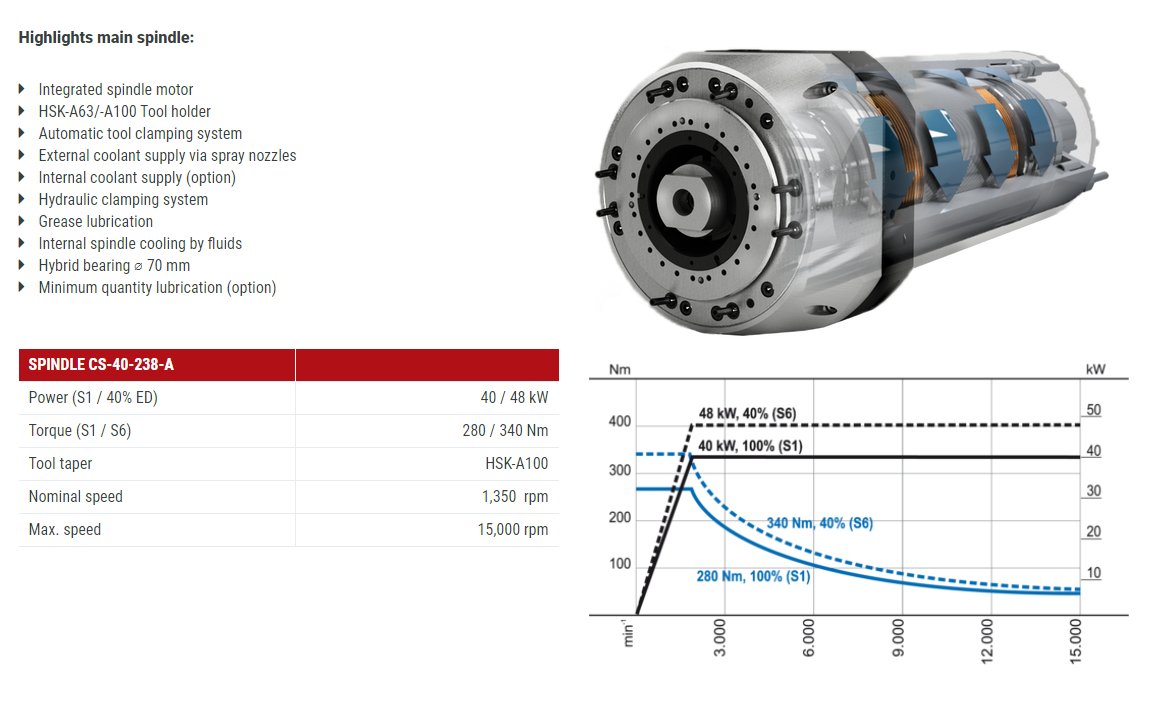

SPINDLE TECHNOLOGY

Pallet Changer

The machines MCV 1060 and MCV 1260 can be optionally equipped with an automatic pallet changer. This convinces with a fast pallet change time of only 15 seconds. The maximum load weight is 900 kg and also allows the automatic changing of heavy workpieces

Dual pallet size: 1.320 x 620 mm

Changing time: 15 s

Loading weight: 900 kg

Fully automatic Plug & Play

Retrofittablen this text to edit it.

Specification Sheets - MCV Series

|

|

MCV 1060 |

MCV 1260 |

MCV 1680 |

MCV 2080 |

|

Working Area |

|

|

|

|

|

Travel Range X / Y / Z |

1,050 x 640 x 800mm |

1,300 x 640 x 800mm |

1,650 x 810 x 810mm |

2,030 x 810 x 810mm |

|

Rapid Traverse X / Y / Z |

40m/min |

40m/min |

30m/min |

30m/min |

|

Acceleration X / Y / Z |

5 m / s² |

5 m / s² |

5 m / s² |

3.5 m / s² |

|

Clamping Surface |

1,320 x 620mm |

1,500 x 620mm |

1,800 x 780mm |

2,200 x 780mm |

|

Maximum Table Load |

1,350kg |

1,350kg |

2,500kg |

3,000kg |

|

Control System |

|

|

|

|

|

Control |

Fanuc / Siemens / Heidenhain |

Fanuc / Siemens / Heidenhain |

Fanuc / Siemens / Heidenhain |

Fanuc / Siemens / Heidenhain |

|

Pallet Changer |

|

|

|

|

|

Clamping Surface Pallet |

1,320 x 620mm |

1,320 x 620mm |

N/A |

N/A |

|

Maximum Load |

900kg |

900kg |

N/A |

N/A |

|

Pallet Change Time |

15sec |

15sec |

N/A |

N/A |

|

No of T-Slots x Width x Pitch |

5 x 18mm x 125mm |

5 x 18mm x 125mm |

N/A |

N/A |

|

Spindle CS-40-238-A (Std) |

|

|

|

|

|

Power (S1 / S6) |

40 / 48kw |

40 / 48kw |

40 / 48kw |

40 / 48kw |

|

Torque (S1 / S6) |

280 / 340Nm |

280 / 340Nm |

280 / 340Nm |

180 / 340Nm |

|

Tool Taper |

HSK-A100 |

HSK-A100 |

HSK-A100 |

HSK-A100 |

|

Nominal Speed |

1,350rpm |

1,350rpm |

1,350rpm |

1,350rpm |

|

Maximum Speed |

15,000rpm |

15,000rpm |

15.000rpm |

15,000rpm |

|

Accuracy ACC. VDI / DGQ 3441 |

|

|

|

|

|

Measuring System |

Direct |

Direct |

Direct |

Direct |

|

Positioning Accuracy X / Y / Z |

0.008mm |

0.008mm |

0.009mm |

0.009mm |

|

Repeatability X / Y / Z |

0.005mm |

0.005mm |

0.005mm |

0.005mm |

|

Tool Magazine HSK-A100 |

|

|

|

|

|

Number of Pockets |

24 |

24 |

24 |

24 |

|

Maximum Tool Diameter |

110mm / 210mm (Empty Space) |

110mm/210mm (Empty Space) |

110mm/210mm (Empty Space) |

110mm/210mm (Empty Space) |

|

Maximum Tool Length |

350mm |

350mm |

350mm |

350mm |

|

Maximum Tool Weight |

20kg |

20kg |

20kg |

20kg |

|

Tool Change Time - Right Hand Changer |

2.9sec |

2.9sec |

4.5sec |

4.5sec |

|

Tool Change Time - Left Hand Changer |

3.9sec |

3.9sec |

N/A |

N/A |

Our motor spindles impress with fast run-up times and highest quality. Innovative sensor technology permanently monitors the milling process and ensures trouble-free production. Optimum heat dissipation is guaranteed by the optimised machine design and the water cooling system integrated into the spindle. In addition to the standard main spindle, other spindle options are available for you.