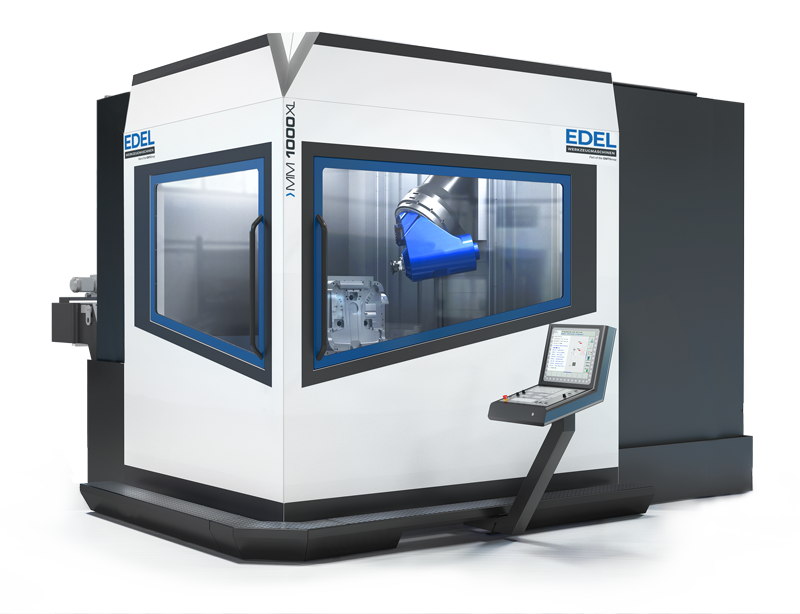

EDEL - MULTIMILL Series

Highly dynamic 5-axis simultaneous machining

EDEL machines are characterised by the optimal synergy between the three core components of the machine tool. Thanks to a close technological partnership to develop core components such as swivel milling heads, spindles, and rotary tables, we can now offer our customers manufacturing solutions that are specially tailored to their requirements, even beyond the usual standards.

Call BSA Tools Ltd - Customer Service Department for full Details !!

HIGHEST QUALITY

EQUIPMENT & VARIANTS

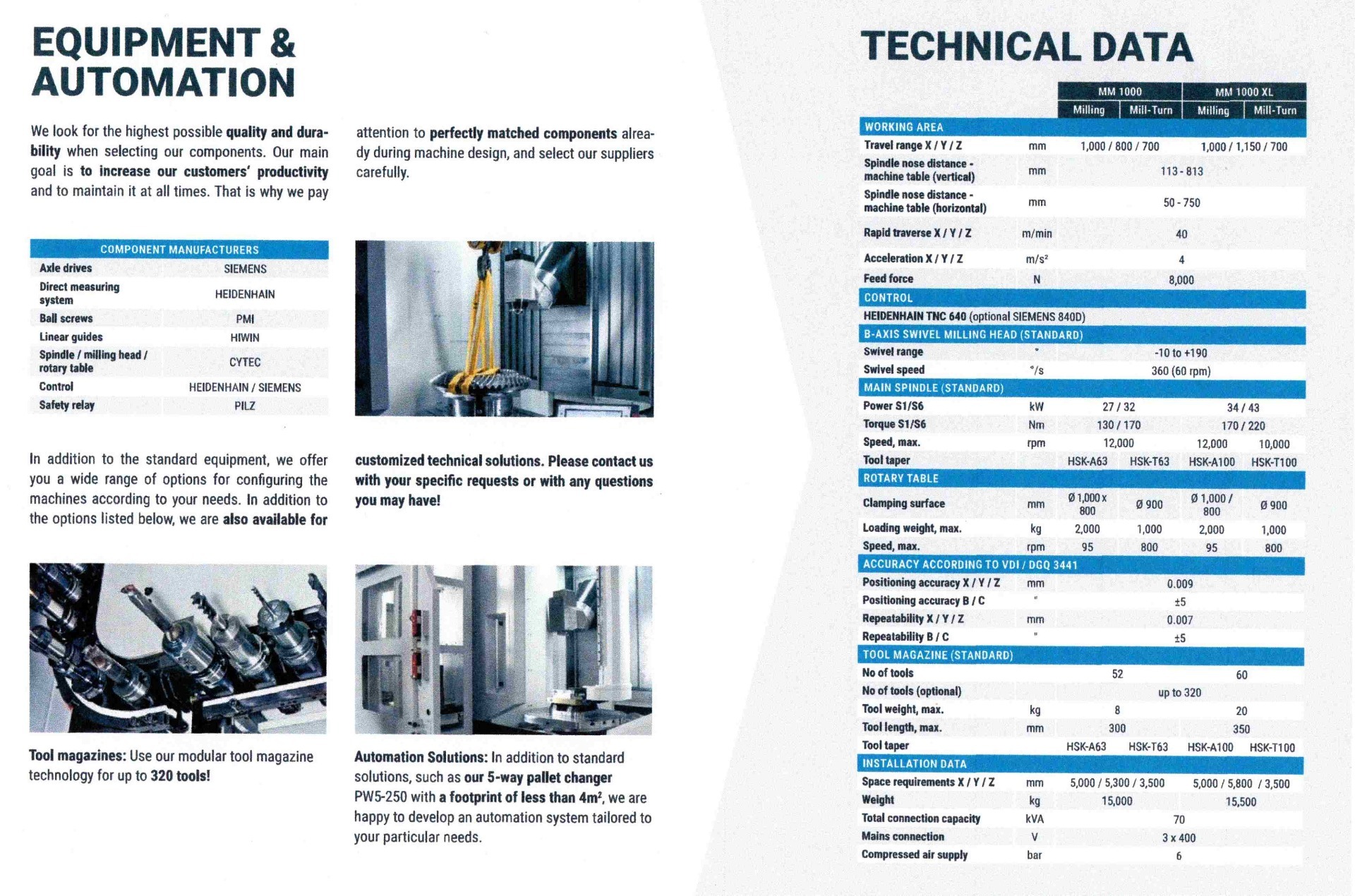

We look for the highest possible quality and durability when selecting our components.

Our main goal is to increase our customers' productivity and to maintain it at all times. That is why we pay attention to perfectly matched components already during machine design and select our suppliers carefully.

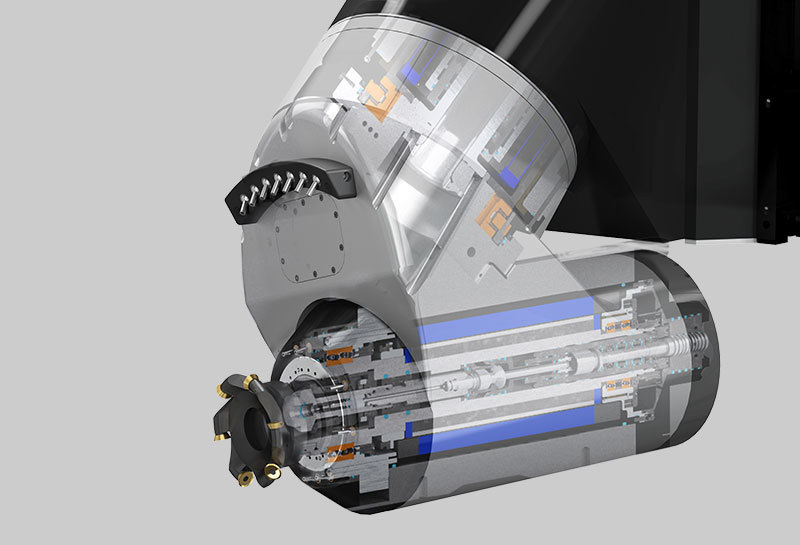

Swivel Milling Heads

Direct drive with torque motors

Swivel range from -10° to +187°

Very high acceleration values

Excellent positioning accuracy

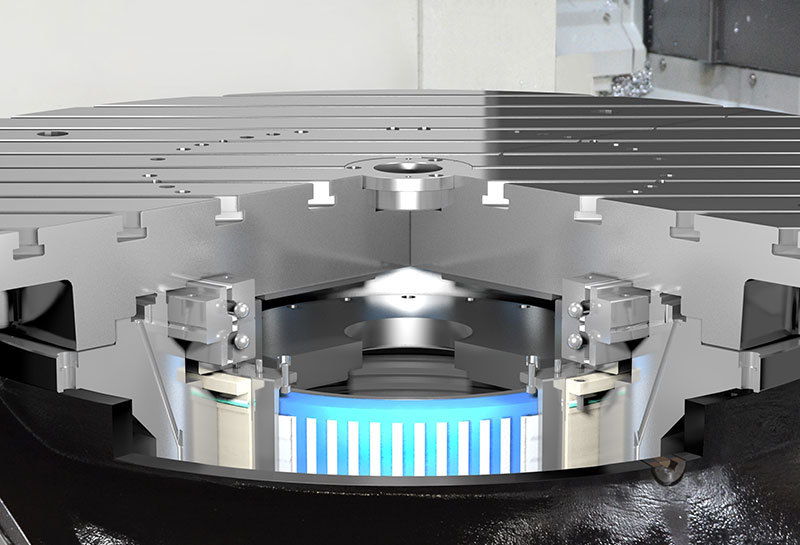

Pivoting Rotary Table

Direct drive with torque motor

Individually configurable table surfaces

Very high acceleration values

Highly accurate positioning

Integrated zero-point clamping system

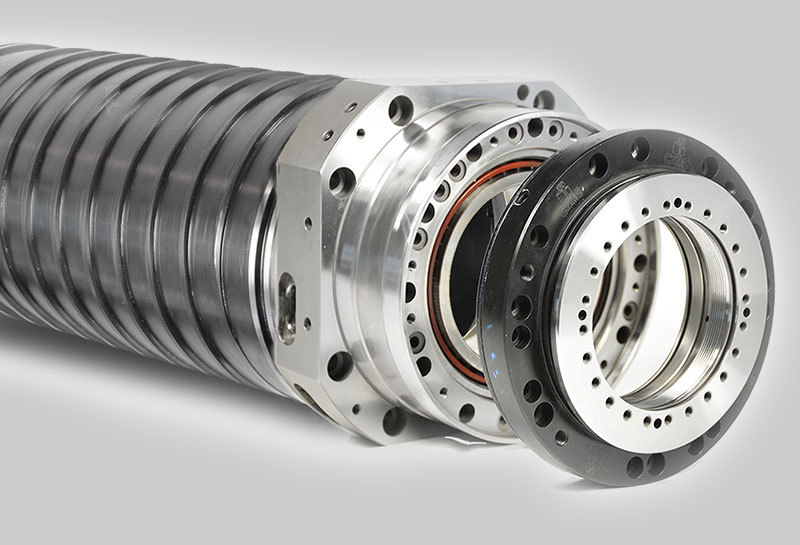

Milling Spindle

Wide selection of spindle options

High-speed HSK-A63 with up to 24,000 rpm

High-torque HSK-A100 with up to 253 Nm torque (S6)

Innovative cooling design

SPINDLE TECHNOLOGY Our motor spindles impress with their fast run-up times and high quality. Innovative sensor technologies constantly monitor the milling processes and guarantee smooth operation. An optimised machine design and water cooling directly integrated into the spindle guarantees for optimal heat extraction.

Specification Sheet

|

WORKING CONTROL |

MULTIMILL MM 1000 XL |

|

Travel Range - X / Y / Z axes |

1000 x 1,050 x 700mm |

|

Rapid Traverse X / Y / Z axes |

40 / 40 / 40 m/min |

|

Acceleration X / Y / Z axes |

4 m/s |

|

Feed Force |

8,000 N |

|

Control System |

Heidenhain TC 640 CNC Control |

|

SWIVEL MILLING HEAD B- AXIS |

|

|

Swivel Range |

-10 bis +187 |

|

Swivel Speed |

330 °/s |

|

Torque Nominal / Maximum |

900 / 1,680 Nm |

|

Clamping Force |

4,000 Nm |

|

Positioning Accuracy |

± 2 |

|

MAIN SPINDLE |

|

|

Power S1 / S6 |

27 / 32 kw |

|

Torque, Maximum S1 / S6 |

139 / 170 Nm |

|

Speed, Maximum |

12,000 rpm |

|

Tool Taper |

HSK-T63 |

|

ROTARY TABLE |

|

|

Clamping Surface |

900mm Diameter |

|

Table Load Centric - Maximum |

20,000 Nm (Fräsen) / 10,000 Nm (Drehen) |

|

Speed - Maximum |

600 min |

|

Torque Nominal / Maimum |

1,130 / 2,065 Nm |

|

Clamping Force |

4,000 Nm |

|

Positioning Accuracy |

± 2,5 |

|

TOOL MAGAZINE |

|

|

Tool Pockets |

52 or 60 |

|

Tool Weight, Maximum |

8 kg |

|

Tool Length, Maximum |

300 mm |

|

Tool Taper |

HSK-T63 |

|

INSTALLATION DATA |

|

|

Machine Foot Print |

5,000 / 5,800 / 3,500 mm |

|

Machine Weight |

15,000 kg |

|

Power Requirements |

70 KVA |

|

Connection Supply |

400v x 3ph x 50hz |

|

Air Supply Requirement |

6 bar |

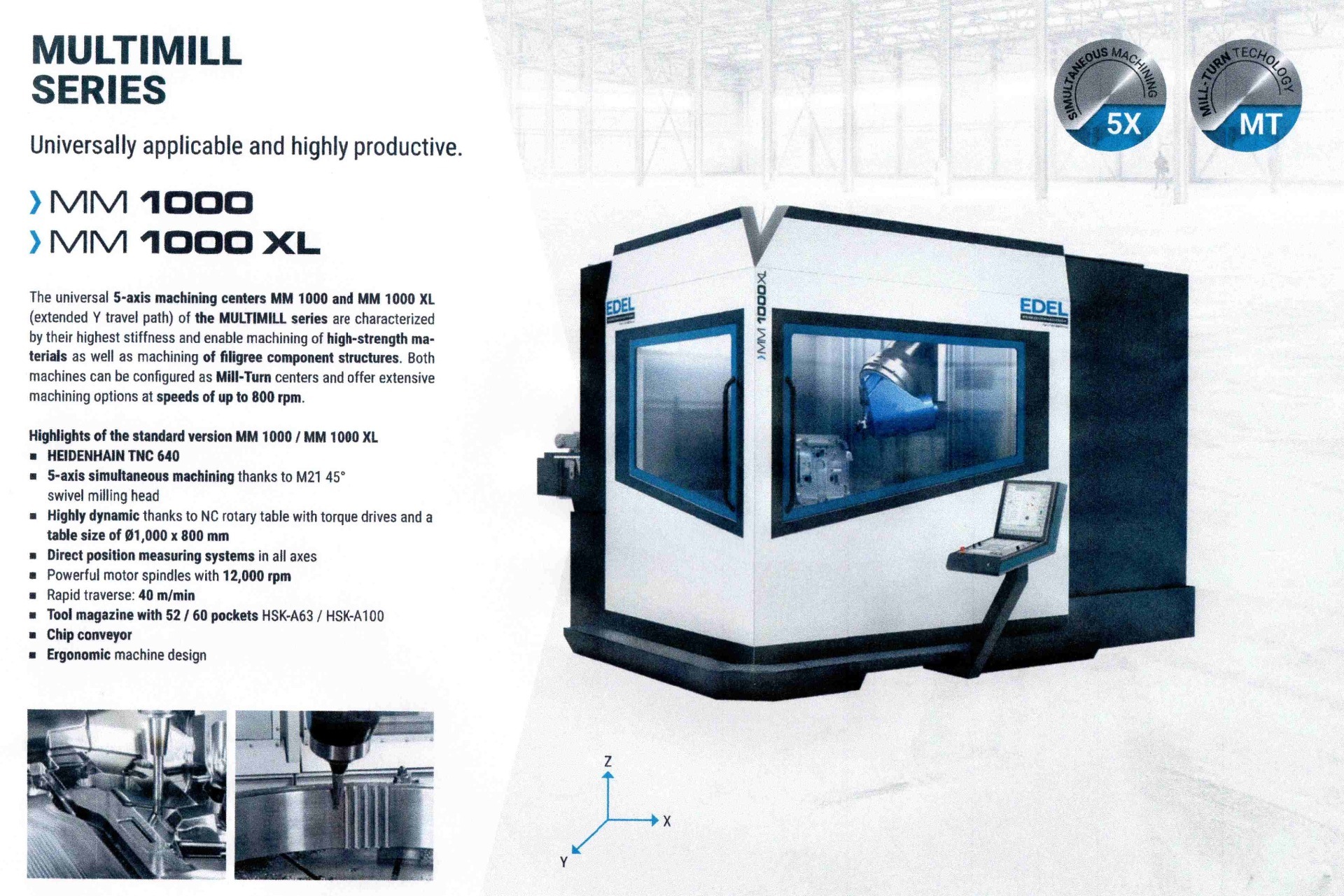

The Universal 5-axis machining centres MM 1000 and MM 1000 XL (extended Y travel path) of the MULTIMILL series are characterised by their highest stiffness and enable machining of high-strength materials as well as machining of filigree component structures. Both machines can be configured as Mill-Turn centres and offer extensive machining options at speeds of up to 800 rpm.

STANDARD EQUIPMENT

Highlights of the standard version MM 1000 / MM 1000 XL

HEIDENHAIN TNC 640

5-axis simultaneous machining thanks to M21 45°

swivel milling head

Highly dynamic thanks to NC rotary table with torque drives and a

table size of Ø1,000 x 800 mm

Direct position measuring systems in all axes

Powerful motor spindles with 12,000 rpm

Rapid traverse: 40 m/min

Tool magazine with 52 / 60 pockets HSK-A63 / HSK-A100

Chip conveyor

Ergonomic machine design

OPTIONS AVAILBLE

SIEMENS 840D

In addition to the STANDARD EWQUIPMENT we offer the following:

Large Capacity Tool Magazines - up to 320 Tools.

Automation Solutions including:

5 Way Pallet Changer - Small Foot Print

Tailored Solutions.